From material engineering to product design and mechanical drafting, the Engineering team at DSTI takes great pride in finding solutions to the most challenging design problems.

Careers in Engineering

We Offer

Clean & Modern, Climate Controlled 80,000 Sq. Ft. Facility

Flexible Hours that Fit Your Schedule

Fun, Collaborative Working Environment

Industry-Leading Manufacturing & Software Technology

Custom In-House Product Testing & Equipment

We’re Looking For

Willingness to Evolve as we Continue to Grow

Strong Communication, Collaboration & Adaptability Skills

Systematic Problem Solving Skills in Diverse Applications

Maturity, Professionalism & Logical Thinking

A Positive, Can-Do Attitude

We Rise to Any Challenge

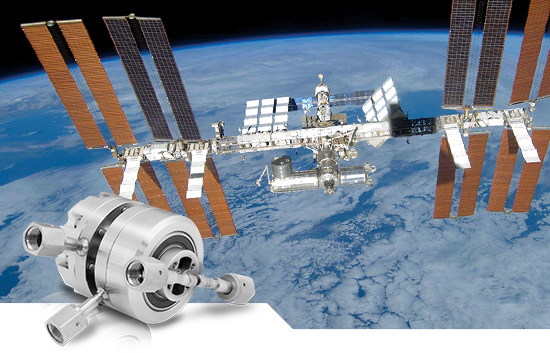

Furthering Space Innovation with Advanced Radiator Technology

DSTI's engineering team designed a fluid and electrical transfer solution for a new thermal control system, allowing spacecraft to be outfitted with steerable (rotating) radiators capable of being directed away from the sun's powerful rays; reducing the need for large radiators and allowing more on-board "real estate".

After extensive dynamic testing and engineering refinements, DSTI's space-ready fluid rotary union design met the project's requirements reducing thermal loss from vapor to liquid lines and allowing data to communicate to the thermal control system.

New Technology Key to Unlocking Oil & Gas Resources

The Engineering team at DSTI has partnered with the world’s leading oil & gas companies to design a product that helps reduce risk and installation time by integrating advanced subsea swivel technology in flexible flow lines used for oil production. As the connection is lowered to the sea floor the swivel allows the lines to move freely without resistance; reducing the amount of stress and loads being applied to the connection equipment.

Specialized bearing design and metal-to-metal sealing technology is used to endure the harsh underwater conditions; including depths reaching more than 11,000 FT and pressures exceeding 10,000 PSI.

Cool Technology for Advanced Radar Systems

DSTI’s engineering team worked with a leading provider of high-tech radar, communication and electronic warfare systems to develop a specialized fluid rotary union with a mechanical face seal engineered to meet the cooling demands for air, land and sea radar systems for military applications.

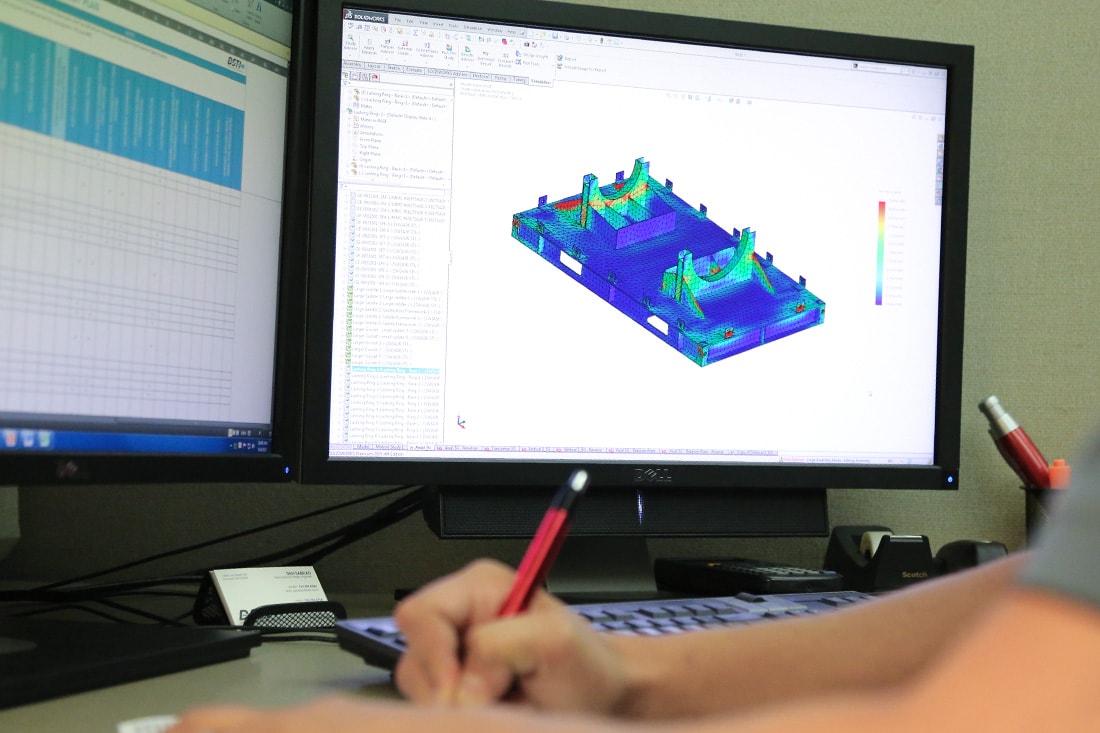

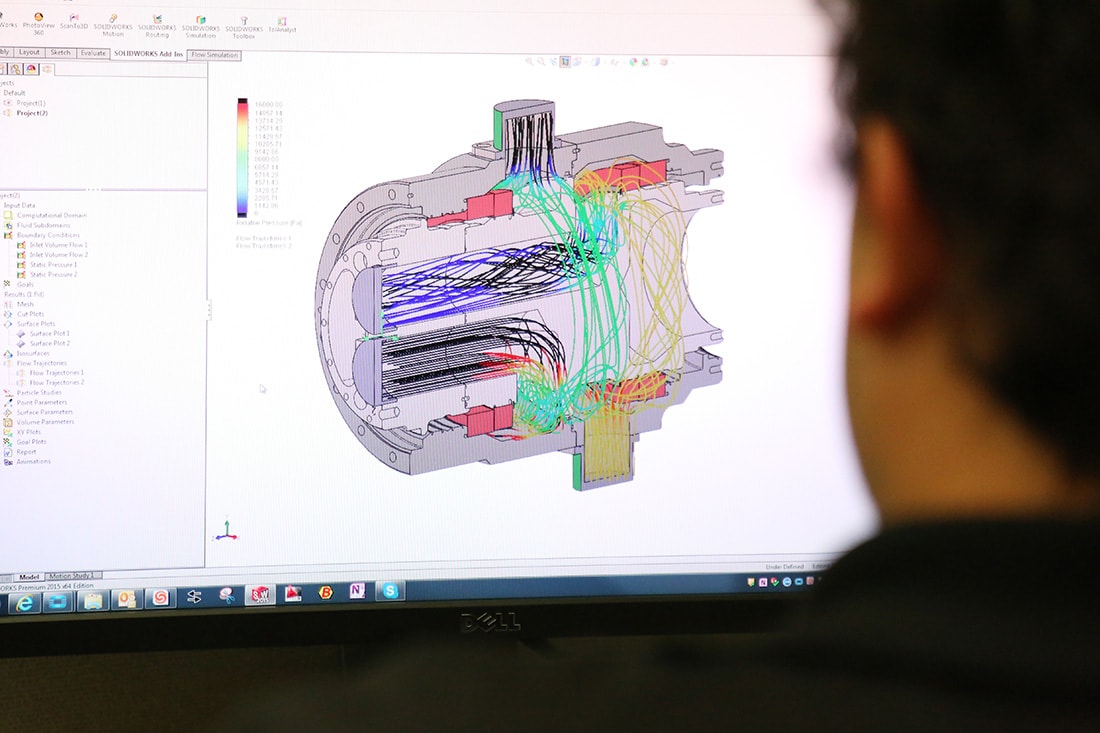

The Active Electronically Scanned Array (AESA) radar system underwent and passed strict testing including five thermal cycles with temperatures ranging from -40°F to 160°F, a 100-hour media flow test, Computational Fluid Dynamics (CFD) and Finite Element Analysis (FEA).

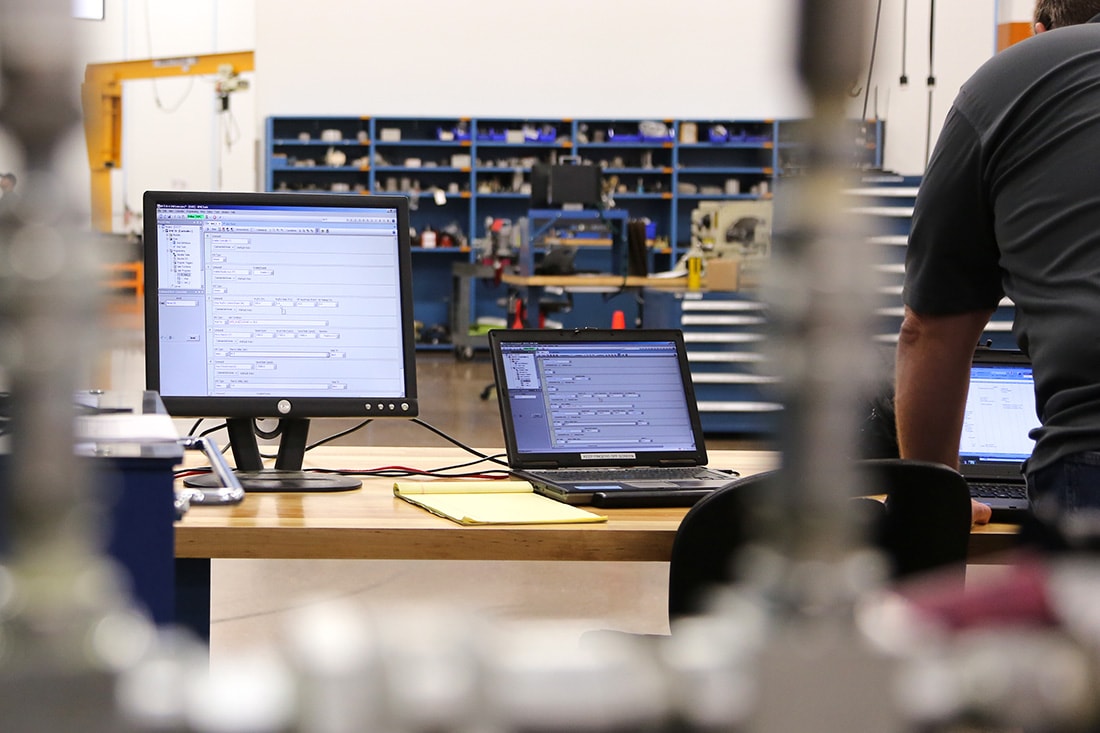

Software and Testing Equipment

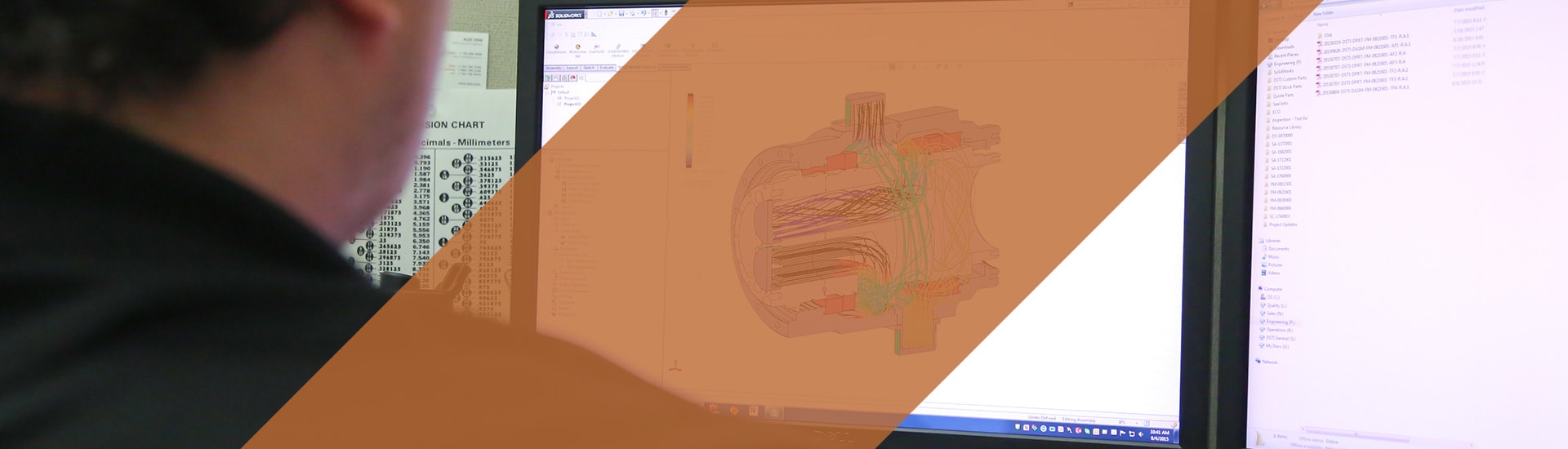

Create, analyze and validate parts and assemblies with the latest professional software.

- Solidworks 3D CAD

- Solidworks Simulation FEA

- Solidworks Flow Simulation CFD

- Epicor ERP

- Auto CAD

Custom test equipment is available to engineers for design verification.

- Custom Large Test Stand (3,000,000 lbf)

- Custom Small Test Stand (1,000,000 lbf)

- Data Collection Tools

- High Pressure Testing

Want To Be Considered For Future Openings?

Although, we may not have Engineering openings today, we are always on the lookout for talented people to join our team.

What DSTI Engineers are Saying

"DSTI has great people, great challenges, and an always changing and growing environment."

"I have the opportunity to make a real and lasting impact on a young, rapidly growing company."

"This company allows you to think for yourself and is willing to listen to any ideas you may have."

"I don't know how a company could try harder to communicate what it knows."

"It's not about being the fastest or cheapest. It's about being the best."

"Management understands their employees have families and personal lives and has a very flexible schedule to work around your home life."